EPE vegetable and fish foam boxes making machine

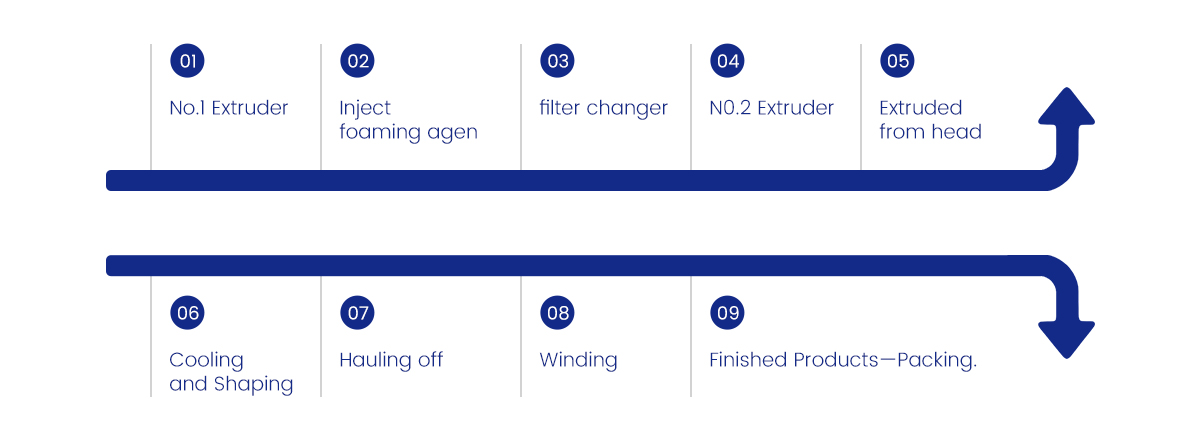

working process

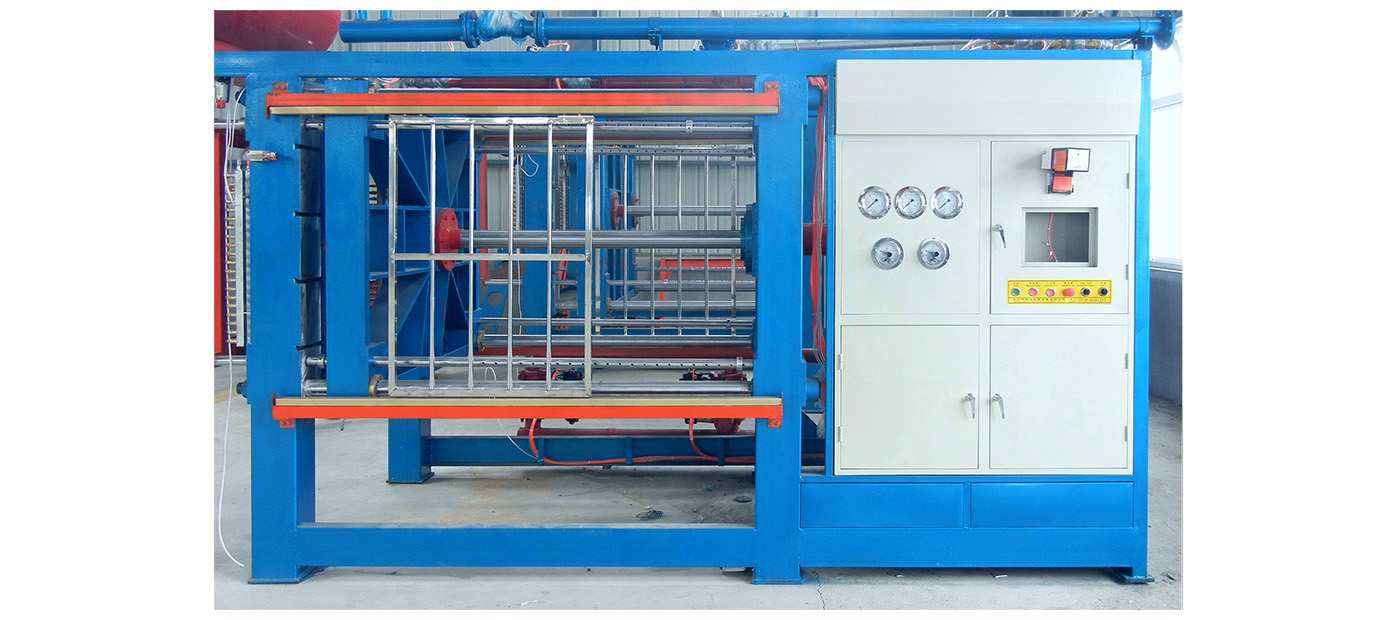

Machine Description

This machine can carry out heating, cooling, feeding and ingot stripping process to adapt to different EPS products.Vacuum system accelerates product shaping speed, shorts the cooling time, reduce product water content.Optimized design is clear and easy with high intensity and high performance-price rate.

PLC System

With PLC English touch screen to realize full automatic production for feeding, advanced moulding technique and can produce various shapes of EPS products.heating,wind cooling, mould opening, mould closing and ejecting the foam box and different shapes.

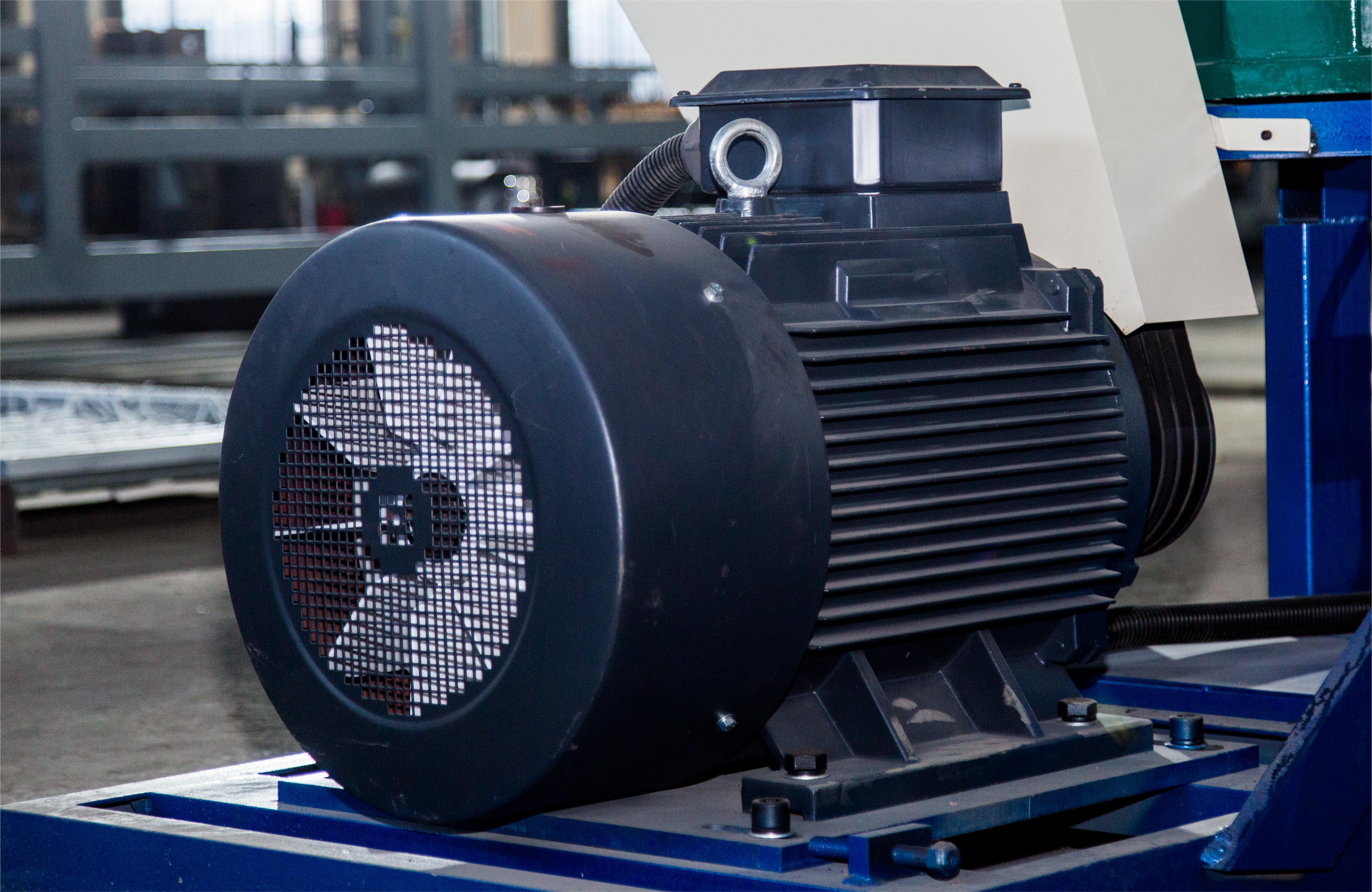

Motor System

This machine applies advanced electrical and hydraulic integration system,which improves the moulding speed,lowers the energy consumption remarkably and reduces the environmental pollution.Perfect malfunction checkout system and motor protecting system which guarantees safe running of equipment.

EPS Moulds

1.EPS Mould is made of high-quality aluminum material, and mould frame is made by extruded aluminum alloy profile, strong andlong lasting.

2.EPS Mould are processed by CNC machines, mould sizes are precise.

3.All cavities and cores are covered by Teflon coating to guarantee easy demoulding.