EPS foam cup machine production line

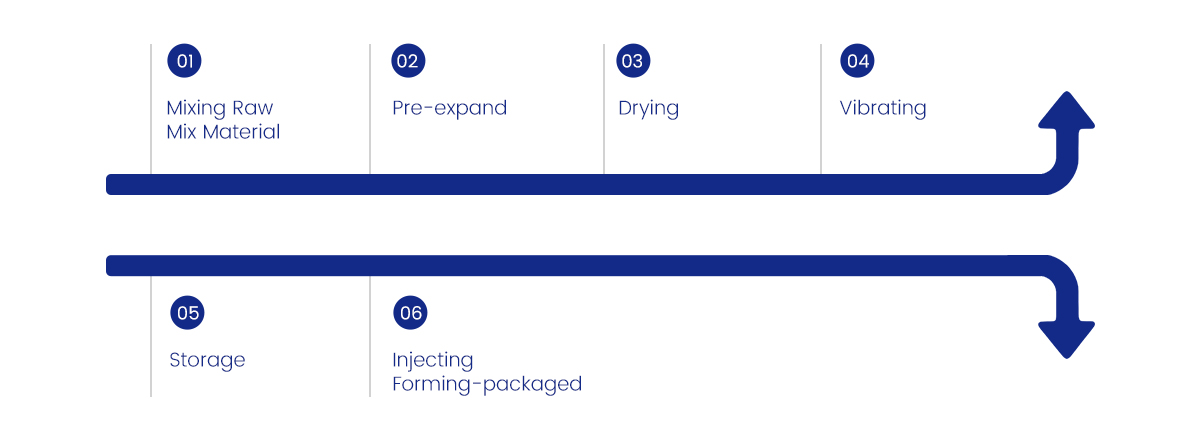

working process

machine description

Advanced molding technique and can produce various shapes of EPS products. This machine can provide different kinds of foam articles with lower moisture content, high foaming speed and lower consumption of energy.This machine can choose vacuum condensation spray system which can significantly improve the efficiency of the vacuum function to achieve saving energy, guaranteed to work properly pressurized water tank under low pressure condition. This machine has microcomputer control and touch screen display. It can function high efficiently under computer control and management with high automation. Simplicity of operation and easy to maintain, it can reduce the labor intensity.

Cup Mould

The mold can be strengthened by heat treatment, with good casting performance, no tendency of thermal cracking, high air tightness, small shrinkage, and the thickness of the shell is thin and uniform when the strength is sufficient.

PLC control system

This machine applies PLC program control and touch screen human-machine control, low voltage and high efficiency special forming process control software that can produce a variety of products.