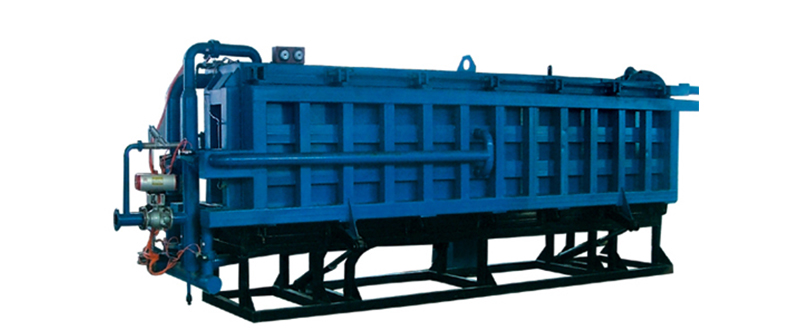

EPS Foam Plate Sheet Block Moulding Machine

working process

machine description

EPS block production line applies advanced EPS heat penetration process and optimized structure of pipelines together and unique heating and molding technology, fast forming, low consumption of steam, low moisture content, which make same high quality interior and exterior and reliable design makes the operation and production simpler and fault rate lower.transformation blower to sucking materials. features strong penetration, good viscosity.

PLC System

Adopt PLC computer touch screen in screen control to realize automatic circulation work ranged from mold open, mold close, charging, heating, preservation, air cooling, stripping and rejection.

Machine Frame

Adopt high quality steel are welded by strong rectangle tube and steel plate make high strength to keep more safety of the machine; in the machine and combining with heat treatment to strengthen machine intensity,without changing its shape. It can bear expansibility of high intensity product.

Cavity

Adopt special aluminum alloy plate in machine cavity, high thermal conductivity, good extension and long lifetime.All block mold frames are treated by heat-treatment to release the welding stress, so that the frames would not deformed.