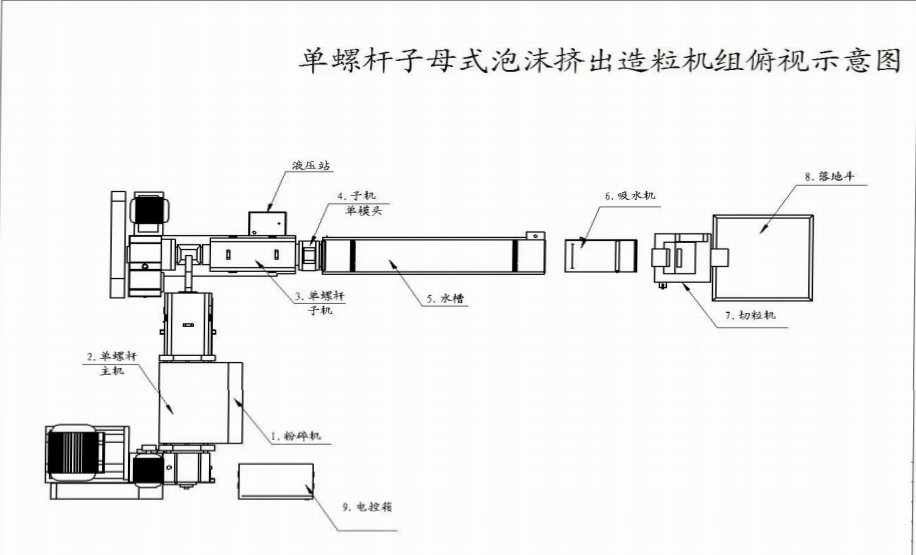

XPS Co2 Foaming Board Extrusion Machine

Machine Description

XPS foam board, named as polystyrene extrusion plastic board (XPS for short) has a flawless closed-pore alveolate structure. Its performances such as the density, water absorption, coefficient of heat conducting and the coefficient of steam pervasion and so on have advantage over those of other board in heat preservation materials and they have the characteristics of strong intensity, light material, airlight, anticorrosion, aging resistance, low cost, etc. It has been used widely in the fields of heat preservation and heat insulation in the construction industry, frost resistance of the highway, railway, airport, square and household fitment. It is generally acknowledged and the best heat preservation material in the market at present.

Feeding System

Two main material feeders: single screw feeder with a motor power of 1.5Kw,

One auxiliary material feeder: a twin-screw feeder with a motor power of 0.75Kw,

One small material feeder: a twin-screw feeder with a motor power of 0.55Kw,

The feeders are all controlled by Taiwan Delta frequency converters for speed regulation.

Host

90KW six level AC motor. Delta frequency converter speed regulation

The main motor speed regulation adopts Delta variable frequency controller

The heating voltage of the host heater is 380V

Traction Machine

Pressure plate specification 1550*850*40mm

A traction power of 2.2KW, Taiwan Delta inverter

Silver tube width 1500mm,diameter 215mm

Traction machine 1.5KW frequency conversion speed regulation

Extrusion Die

The mold can be made with a widtn af 900mm

The mold runner is a coat hanger type.